Industrial valves manufacturer and cast iron foundry

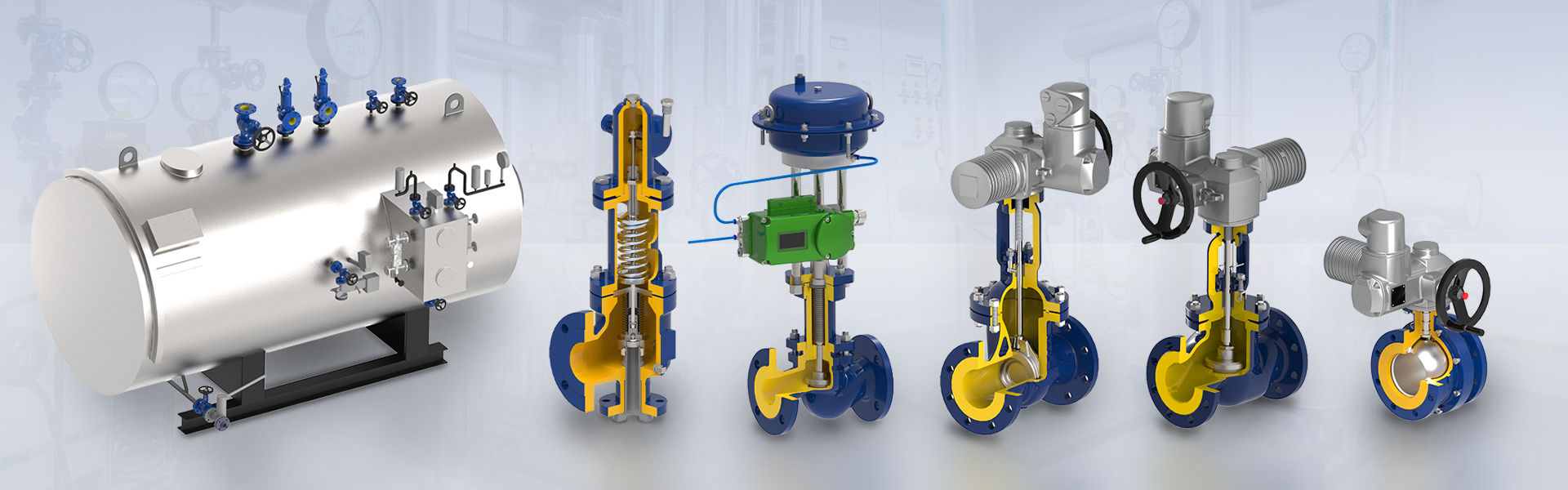

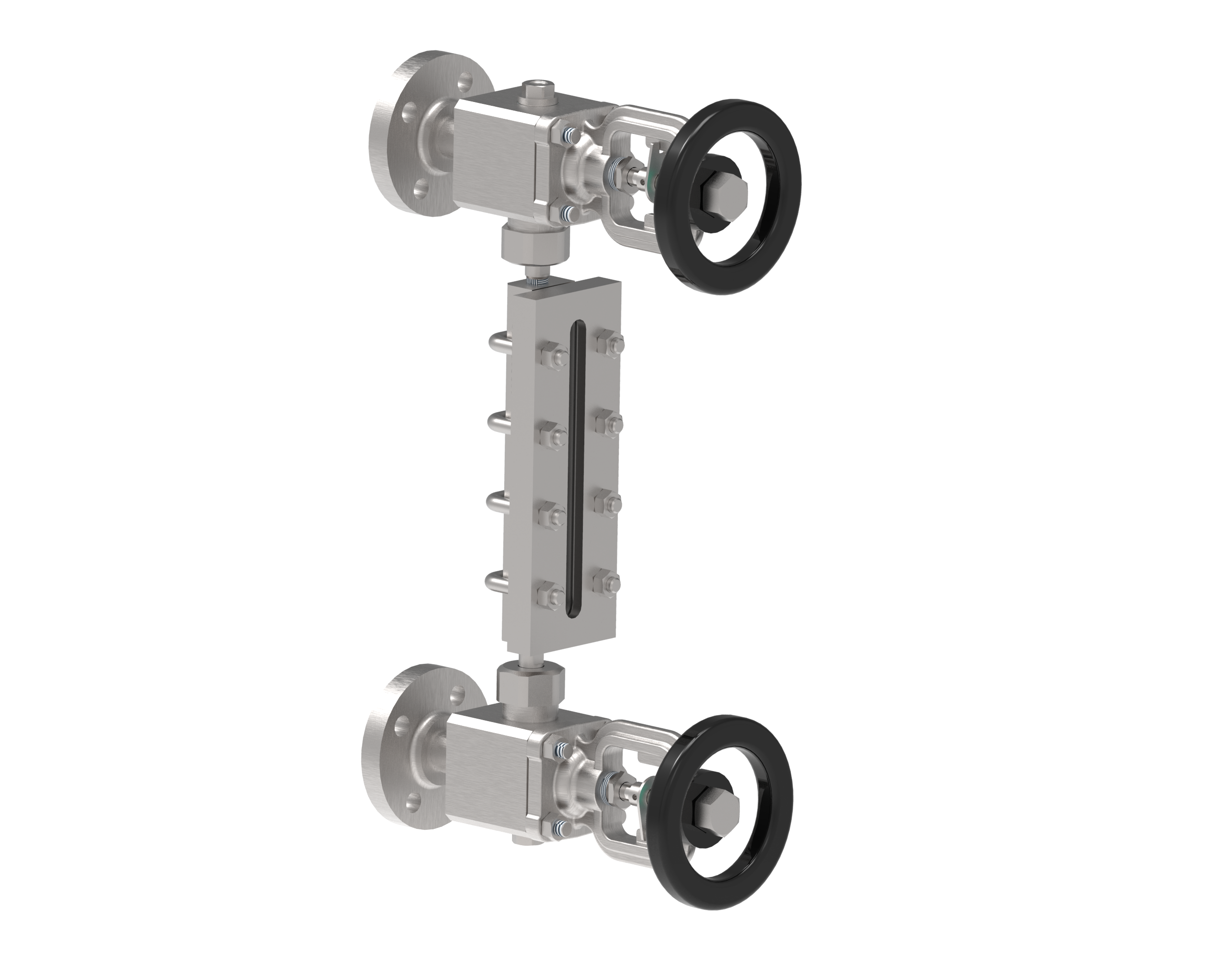

ZETKAMA is a company with 75 years of experience and more than 75 foreign markets, on which sells iron castings and industrial valves, ie. stop valves, bellow valves, control valves, check valves, safety valves, strainers, gate valves, ball valves, backflow preventers, static balancing valves, butterfly valves, rubber expansion joints, float valves, bottom valves, liquid level gauges.

Read more

ZETKAMA is a well-established industrial valves manufacturer and cast iron foundry, recognized across Europe and beyond for delivering precision-engineered solutions to key sectors of industry and infrastructure. With over 75 years of experience in valve design and production, the company combines proven metallurgical expertise with modern manufacturing practices, offering a comprehensive range of industrial valves and custom cast iron components.

Operating from its production facilities in Poland, ZETKAMA supplies OEM manufacturers, system integrators and distributors with heavy-duty, technically advanced valves that meet the highest European standards. In addition to valve production, ZETKAMA runs its own foundry, specializing in high-quality cast iron castings tailored to client requirements. This dual competence allows for full process control — from raw material to final product — ensuring consistency, reliability and long-term value across the product lifecycle.

Valve company with global reach

As one of the most trusted valve companies in Europe, ZETKAMA stands out for its broad international presence and diverse application experience. The company exports to over 70 countries worldwide, supporting industries such as energy and power generation, water and wastewater treatment, chemical and petrochemical processing, district heating, and marine engineering.

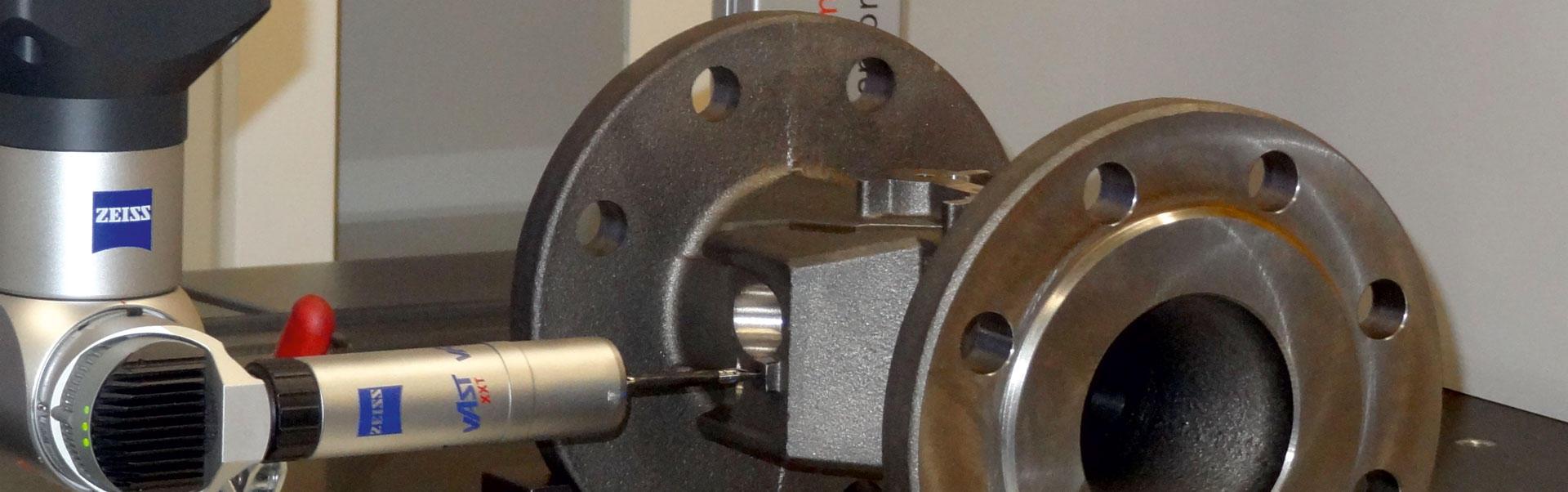

Each project benefits from ZETKAMA’s full-cycle production process — from in-house R&D and laboratory testing, through pattern making and casting, to machining, assembly and final pressure testing. This makes the company a reliable and agile partner among industrial valve suppliers, particularly valued for its responsiveness, product range and technical support. In the competitive landscape of valve manufacturers, ZETKAMA’s ability to deliver customized valve configurations, rapid prototyping and cast iron solutions with short lead times continues to strengthen its global reputation.

Hydraulic valves manufacturer for demanding applications

ZETKAMA’s portfolio includes a wide range of products that classify the company as a reputable hydraulic valves manufacturer. These valves are designed to withstand variable pressure conditions, temperature fluctuations and the specific dynamics of hydraulic systems. Whether integrated into district heating loops, thermal power plants, or industrial fluid networks, ZETKAMA valves are engineered to ensure minimal pressure loss, reliable flow regulation, and safe shut-off capabilities.

The use of durable materials such as EN-GJL-250 and EN-GJS-400-18 cast iron, combined with sealing elements like EPDM, NBR or graphite, allows the valves to operate reliably in media ranging from water and steam to glycol and air. Available with manual, electric, or pneumatic actuation, ZETKAMA’s hydraulic valves are manufactured to comply with EN, ISO and PED standards, making them suitable for installation in regulated systems throughout the EU and global markets.

Industrial valves manufacturer with wide product portfolio

As a complete industrial valves manufacturer, ZETKAMA offers over 2,000 product configurations — from basic shut-off valves to complex flow control and safety devices. The assortment includes globe valves, check valves, bellow-sealed valves, strainers, butterfly valves, ball valves, knife gate valves, pressure reducing valves, and float valves. Each type is available in a variety of materials, pressure classes (PN6–PN40), and connection standards (flanged, threaded, welded).

The company’s valves are designed with long-term functionality and maintainability in mind, and they are tested according to EN 12266-1, ensuring a high level of tightness and mechanical resistance. With decades of field-proven installations, ZETKAMA continues to be a preferred partner for engineering firms and industrial plant managers seeking robust and cost-effective valve systems that meet both functional and legal requirements.

Heavy duty valves manufacturer with in-house engineering

In critical applications involving high pressure, high temperature, or aggressive media, ZETKAMA performs as a reliable heavy duty valves manufacturer. The company’s engineering team develops valve designs tailored to harsh operating environments, including power boilers, industrial heating systems, and pressurized process loops. These valves are made from carefully selected materials — including high-grade ductile iron, stainless steel internal elements, and corrosion-resistant coatings — to ensure durability even in the most demanding conditions.

Every product undergoes pressure and leakage testing, and can be supplied with certificates of compliance for regulated installations. By managing every stage of production — from casting to machining, assembly and final inspection — ZETKAMA guarantees both structural integrity and dimensional accuracy, setting itself apart in the segment of heavy-duty industrial valves.

Control valve manufacturers for precision flow regulation

As one of Europe’s experienced control valve manufacturers, ZETKAMA delivers solutions that provide precise regulation of flow and pressure in industrial systems. Control valves are available with pneumatic actuators (spring-open or spring-closed), and can be combined with electro-pneumatic or intelligent digital positioners.

This enables proportional control of fluid flow based on external signals, making these valves suitable for automation systems in HVAC, chemical dosing, or energy management. ZETKAMA’s control valves feature equal percentage flow characteristics, enhancing system stability and efficiency. The valves are available in DN15–DN150 sizes, with pressure ratings up to PN40, and body materials selected based on fluid compatibility. Tested in accordance with EN 60534-4 and PED 2014/68/EU, they guarantee leakproofness class IV and can operate in temperatures from –10°C to +300°C depending on configuration.

Safety relief valve manufacturers protecting system integrity

ZETKAMA’s range includes spring-loaded valves that establish the company as one of the trusted safety relief valve manufacturers in Europe. These valves protect pressurized systems from overpressure by releasing excess medium when a predefined pressure threshold is exceeded.

Designed according to strict standards and manufactured from cast iron or stainless steel, ZETKAMA safety valves are suitable for steam, air, gas and liquid media. Available in flanged and threaded versions, they ensure high sealing tightness and fast response time, contributing to the operational safety of boilers, tanks, and pipelines.

Stop valve manufacturers ensuring media separation

ZETKAMA is also a leading stop valve manufacturer, offering globe-type and bellow-sealed designs that allow complete shut-off of flow in industrial systems. These valves are essential in scenarios where full media separation is required for maintenance, safety or process control. Thanks to corrosion-resistant internals and high-quality sealing, ZETKAMA stop valves operate reliably under frequent cycling and in thermally dynamic conditions.

Cast iron foundry with integrated production model

ZETKAMA’s foundry is a strategic advantage that supports its position not only as a valve producer, but also as a specialist in cast iron castings. The company produces grey and ductile iron parts for internal valve components and for third-party clients. This integrated model ensures traceability, repeatable quality and material consistency from melt to machining. The foundry supports custom cast iron production for OEM clients in sectors such as pump manufacturing, automotive, energy and industrial machinery.

Custom cast iron castings for OEM applications

With advanced molding, pattern-making, and core-forming facilities, ZETKAMA delivers custom cast iron solutions tailored to customer specifications. Whether producing short series or larger batches, the company supports clients with full technical documentation, dimensional accuracy and metallurgical quality assurance. From functional housings to load-bearing mechanical parts, ZETKAMA’s castings meet demanding mechanical, thermal and chemical resistance criteria, supporting clients in reducing lead times and simplifying supply chains.

Engineering excellence backed by experience

Combining the precision of a modern production facility with the legacy of decades-long engineering experience, ZETKAMA is more than just a supplier — it is a strategic partner for companies seeking industrial valve solutions and cast iron components of verified quality. With full in-house control, fast prototyping capabilities and a global distribution network, ZETKAMA continues to raise the standard among valve companies, providing reliable infrastructure for industries that build the world.